The first Banjoworks workshop ran during the school Easter holidays, over nine days.

- Three S1 pupils (twelve years of age) and one former pupil attended.

- Two of the pupils, Daniel Gough and Robbie Ferguson, built their banjos, start to finish in the nine days.

- One pupil, Scott Nicoll could only attend during the five days of the second week. He was provided with a partially formed neck, which allowed him to complete the remainder of the instrument within the time he had available.

- The former pupil, Blair Robertson, attended during the first week. Unfortunately, his employer altered his work schedule for the second week and he was therefore unable to attend to complete his banjo. The partly completed components have been stored, in case he has the opportunity to attend a future workshop, to complete his banjo.

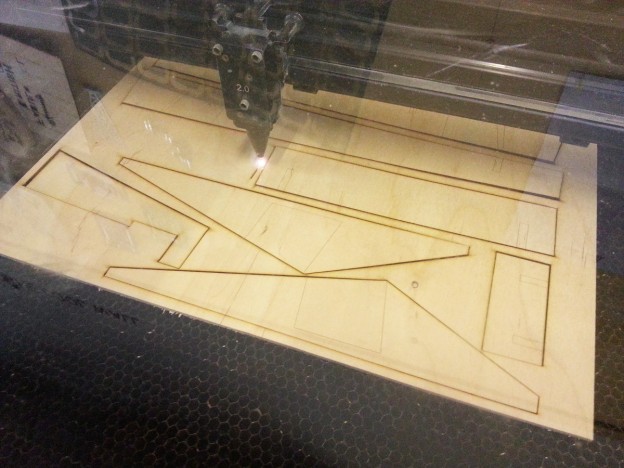

- Faculty leader Bob Baldie was available throughout, and helped Robbie and Daniel prepare CAD drawings to laser cut their peg head inlays.

Links to Photos

- Workshop progress photos, available at Flickr.

- Photos of Robbie Ferguson’s completed banjo, available at Flickr.

- Photos of Scott Nicoll’s completed banjo, available at Flickr.

- Photos of Daniel Gough’s completed banjo, available at Flickr.